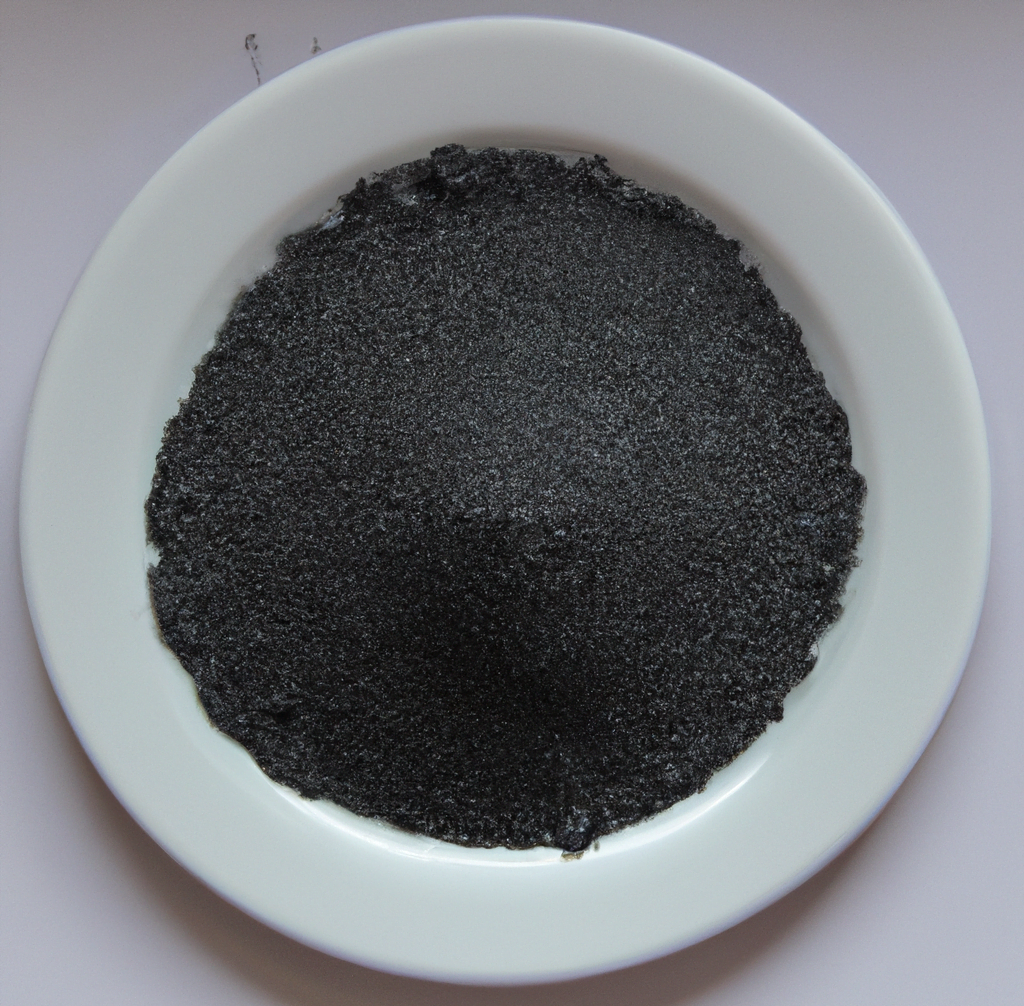

Reduced Iron Powder

Reduced iron powder is a metal powder produced by reducing iron salts using a reducing agent like hydrogen or carbon monoxide at high temperatures. It has wide applications in various industrial and scientific fields.

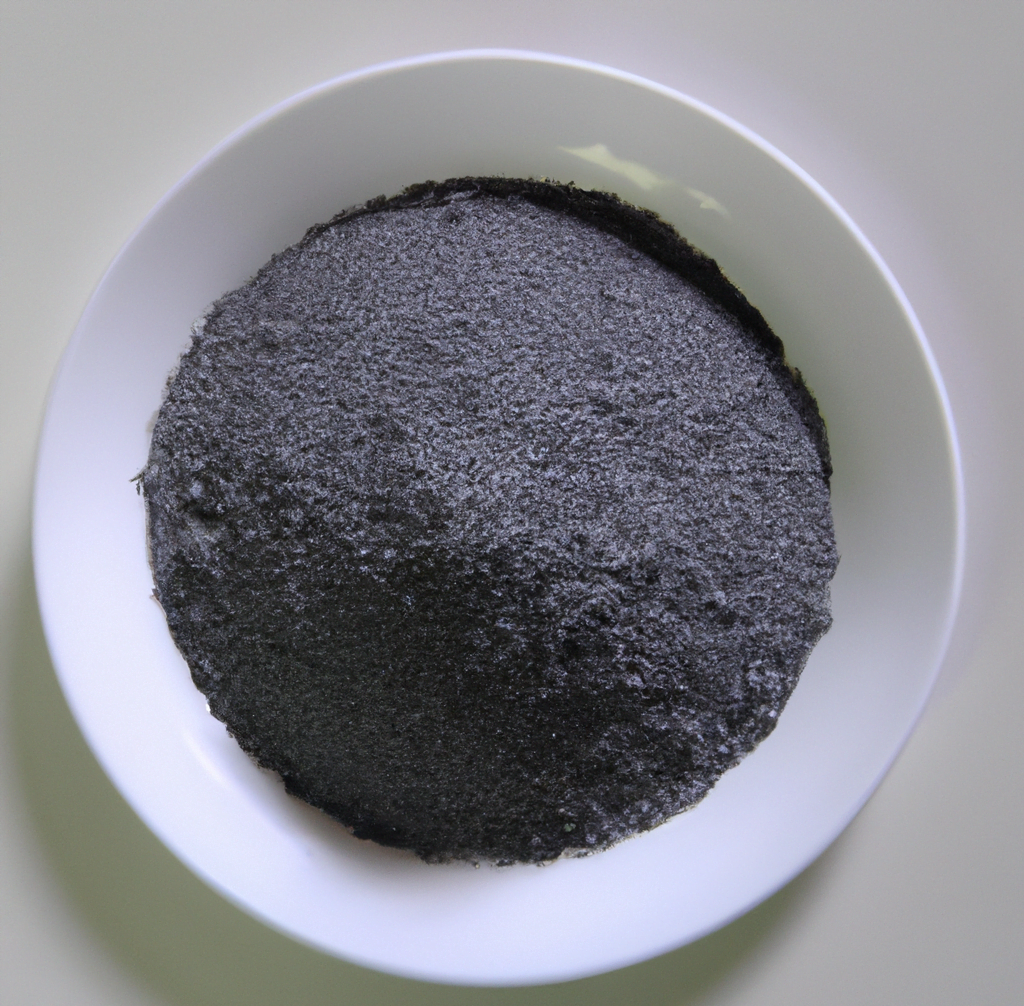

Atomized Iron Powder

Atomized iron powder is a fine metallic powder produced through a process called atomization. The process involves melting iron and then spraying it into a controlled environment, causing the molten iron to disperse into small droplets.

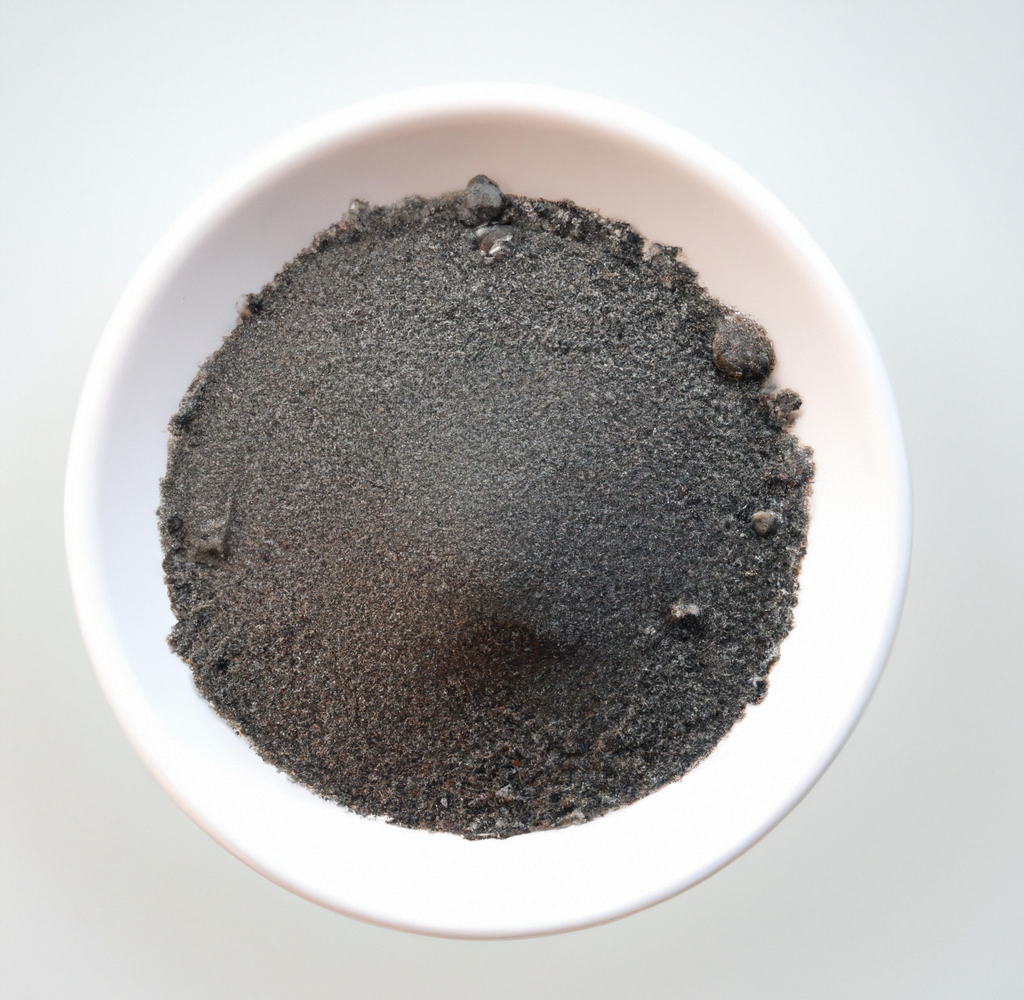

Carbonyl Iron Powder

Carbonyl iron powder is a highly pure, fine iron powder created through the carbonyl process. This method involves heating iron in the presence of carbon monoxide, forming a gaseous compound that decomposes upon cooling, resulting in ultrafine iron particles.

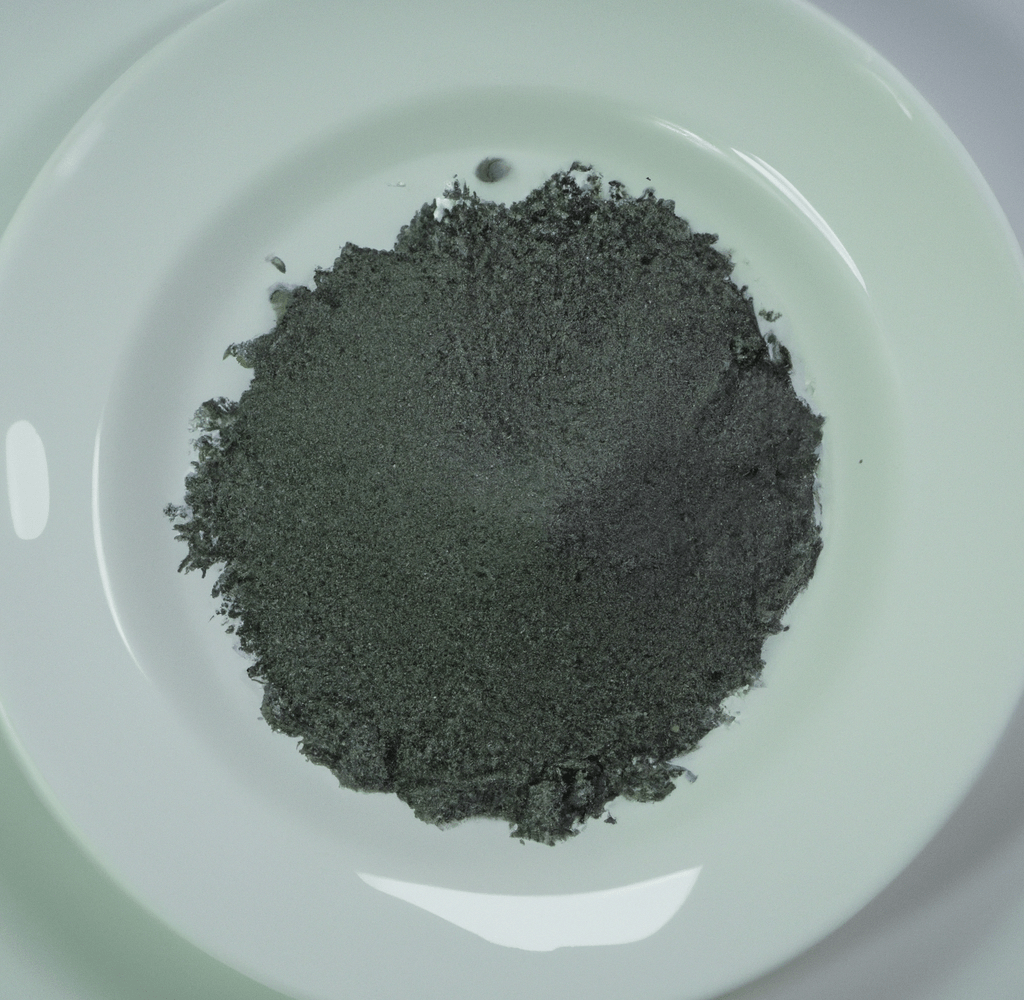

Nodular cast iron powder

Nodular cast iron powder, also known as ductile iron powder, is a form of iron powder with unique graphite nodules dispersed throughout the iron matrix. This distinctive microstructure imparts enhanced ductility, toughness, and wear resistance compared to traditional gray cast iron.

Micro-alloyed Iron Powder

Micro-alloyed iron powder is a type of iron powder that contains small amounts of alloying elements, improving mechanical properties and performance. These trace elements enhance the material's strength, toughness, and wear resistance.

Micro-alloyed Ultrafine Iron Powder

Micro-alloyed ultrafine iron powder is a specialized iron powder that contains trace amounts of alloying elements and exhibits a very small particle size. The combination of micro-alloying and ultrafine particles results in improved mechanical properties, such as enhanced strength and wear resistance.

Zinc-iron Alloy Powder

Zinc-iron alloy powder is a fine metallic powder composed of zinc and iron elements, resulting in a material with unique properties. This alloy powder offers a combination of corrosion resistance from zinc and strength from iron. Its enhanced characteristics provide improved performance in industries where durability and resistance to wear are essential.

Copper-iron alloy powder

Copper-iron alloy powder is a composite metal powder consisting of copper and iron particles. This unique alloy offers a combination of desirable properties from both metals, such as good thermal and electrical conductivity from copper, and high strength and magnetic properties from iron.

Ultrafine phosphorus iron powder

Ultrafine phosphorus iron powder is a high-purity, fine-grained alloy powder composed of iron and phosphorus. It is characterized by its small particle size and excellent magnetic properties. This unique composition offers improved corrosion resistance, wear resistance, and mechanical properties.

Ferrochrome Powder

The ferrochrome powder products we offer are primarily categorized based on carbon content into four main types: ultra-low carbon, low carbon, medium carbon, and high carbon ferrochrome powders.

Ferrosilicon Powder

Ferrosilicon powder is indispensable in many industrial productions. Due to its abundant raw materials and relatively low production costs, the global demand for ferrosilicon powder is substantial. The ferrosilicon powder products we offer are produced through atomization.

Ferrotungsten Powder

Ferrotungsten powder is an alloy powder synthesized from tungsten and iron in specific proportions. Tungsten (W) and iron (Fe) as alloying elements exhibit certain compatibility, forming solid solutions or complementary alloys.

aluminum iron alloy powder

Aluminum iron alloy powder is a powdered alloy formed by mixing aluminum (Al) and iron (Fe). Aluminum iron alloys typically possess better strength and hardness than pure aluminum or pure iron, while their density might fall between the two.

Ferro-molybdenum Powder

Ferro-molybdenum powder is an alloy powder formed by mixing molybdenum (Mo) and iron (Fe) in specific proportions. Molybdenum and iron can form solid solutions or complementary alloys, which exhibit unique physical and chemical properties in certain applications. Ferro-molybdenum has excellent hardness, wear resistance, and high-temperature stability.

Ferrovanadium Powder

Ferrovanadium powder is an alloy powder formed by mixing vanadium (V) and iron (Fe) in specific proportions. Ferrovanadium (FeV) is an essential alloy, primarily used as an alloying element in steel to enhance a range of steel properties. Ferrovanadium alloys exhibit high hardness and strength. They also show good stability for certain chemical and physical processes.

Ferroboron Powder

Ferroboron powder is an alloy powder formed by mixing boron (B) and iron (Fe) in specific proportions. It is a type of soft magnetic material. Due to its outstanding performance in various applications, the market demand for ferroboron alloys has always been high, especially in power electronics and renewable energy technologies.

Ferromanganese Powder

Ferromanganese powder is an alloy powder formed by mixing manganese (Mn) and iron (Fe) in specific proportions. Ferromanganese alloy is an essential alloy, primarily used in the steel industry as a deoxidizer and alloying additive.